Understanding the need and the concept of digital twin software technology for wind energy

As wind turbines continue to grow in size, they are increasingly being deployed offshore. This causes construction and O&M of wind turbines to become more challenging. Digitalization is key in enabling technology to manage wind farms in difficult environments, potentially increasing efficiency and reducing installation and operational and maintenance costs. Digital infrastructure based on Industry 4.0 concept, such as digital twin, enables data collection, visualization, modelling and analysis of wind power analytics at individual turbine or wind farm levels.

A digital twin is a virtual representation of a physical asset or system, offering real-time insights into its behavior, performance, and condition. This technology uses sensors, data analytics, and advanced modelling to create a dynamic and interactive simulation that mirrors the real-world asset. In the context of offshore wind, a digital twin encompasses the entire lifecycle of wind farms, from design and construction to operation and maintenance.

What are some of the key applications for digital twin software technology in the wind industry?

- Design and Planning: Digital twin software technology allows offshore wind developers to create accurate and detailed models of proposed wind farms. These models simulate the interactions between wind, waves, and turbines, aiding in optimizing layouts for maximum energy production while minimizing potential risks.

- Construction and Installation: During construction, digital twins help manage complex logistics and operations. They provide real-time data on weather conditions, vessel positioning, and equipment status, enabling efficient deployment and reducing downtime.

- Operations and Maintenance: A big potential of digital twin technology shines in the operations phase. Real-time data from sensors installed on turbines are fed into the digital twin, allowing operators to monitor the performance and health of each turbine remotely.

- Performance Optimization: Through continuous data collection and analysis, digital twins enable operators to fine-tune operations. Adjustments can be made to turbine settings, blade angles, and other parameters to optimize energy production and enhance overall efficiency.

Optimized modelling with a digital replica of wind farm behaviour and assets

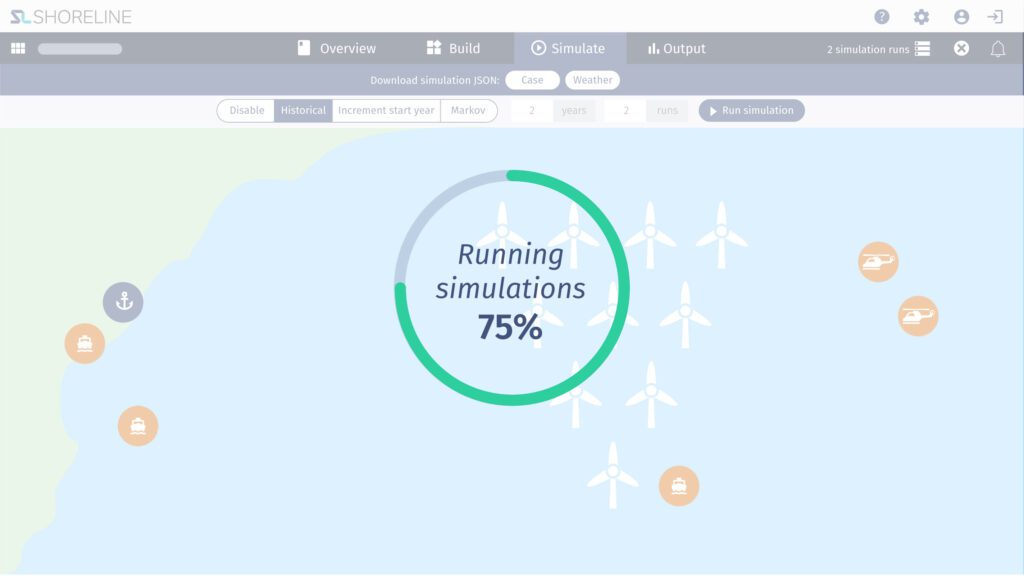

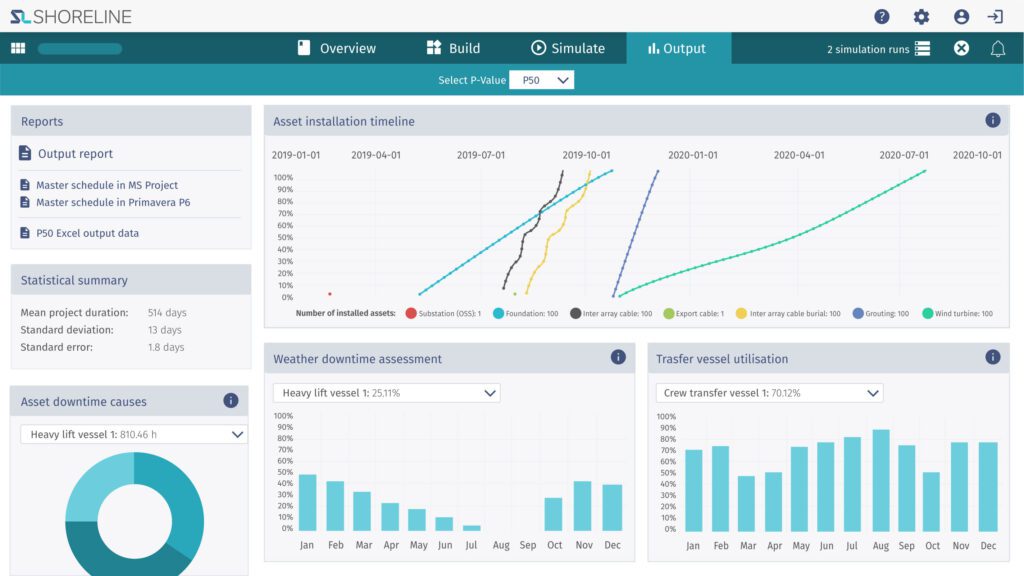

Already used on wind projects globally by some of the largest players in the industry, the Shoreline software creates a digital space for all the workflows, logistics, resources, weather, and assets which can be used in a powerful combination of simulation models and schedule optimization to analyze numerous complex field service, supply chain and project scenarios to find the optimal solution.

The software applies digital twin technology by creating an understanding of how the wind farm logistics would perform before having to build it. This allows users to start virtually simulating many possible wind farm construction and O&M campaigns with various weather windows, alternative port installation logistics, different project start-dates and many more variations. Just to name a few of the scenarios, including shuttling-based installation, simple nearshore CTV-supported O&M operations, complex feeder-based installation, parallel operations, nearshore transportation, shared resource utilization across clusters, batch runs, and much more are covered in the user-friendly application.

The simulation identifies potential faults before they escalate, as its digital twin technology helps prevent unplanned downtime. By providing accurate and real-time data, the platform empowers its users to make informed decisions about operational strategies, maintenance schedules, and resource allocation. Quickly addressing key pain points for its users:

- When should the construction start, considering the historical weather?

- What would be the best feeder configuration for my near-shore project?

- The nearest port has limited loadoff capacity. Can I use another location?

- How many total hours of downtime occur during blade installation?

- The installation area shows very high significant waves. What is the expected downtime for my HLV?

- What is the personnel utilization during commissioning?

- The offshore wind project area shows very high significant waves. What is the expected downtime for my CTV?

- What is the influence of the lead time for HLV operations?

After running the simulations, these questions will be answered by the results in the software’s output report. The report delivers precise estimates on construction duration, weather downtime/root causes, cost, time-based availability, production-based availability, vessel/personnel utilization and many more essential project delivery factors.

Challenges going forward with digital twin software technology for wind energy

While digital twin technology offers transformative benefits, its adoption comes with challenges. These include data security, integration with existing systems, and the need for skilled personnel to manage and interpret the data. However, as technology evolves and becomes more accessible, these challenges are likely to diminish.

Looking ahead, the future of digital twin technology in offshore wind is promising. As machine learning and artificial intelligence advance, digital twins will become even more sophisticated, offering deeper insights and predictive capabilities. .

In the dynamic landscape of offshore wind energy, digital twin software technology stands out as a game-changer. As Shoreline Wind demonstrates, harnessing the power of digital twins can lead to improved efficiency. By embracing this innovative technology, the offshore wind industry is propelling itself towards a more resilient, faster and efficient wind industry.

If you want to explore our digital twin software technology further, you can find this on our product page for the Design software, where you can download brochures for both the construction and O&M versions.

If you have further questions regarding the article, please reach out to Shoreline via our contact page.