The evolution of wind turbine efficiency

Over the last decade, wind renewables have emerged as a promising energy source with the potential to enable a significant shift from reliance on fossil fuels. Given the urgent climate crisis coupled with the economic fallout of the protracted conflict in Ukraine, ensuring widespread adoption of clean, renewable energy is becoming increasingly vital to ensuring global health and safety.

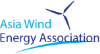

Since the first land-based wind farm was installed in 1980, wind power technology has evolved rapidly over the last few decades with the development of more efficient and taller turbine designs capable of delivering much higher MW outputs than their early predecessors.

The most significant progress in wind technology is occurring within the offshore sector where increasingly gargantuan turbines capable of producing nearly 150 times the output of the first land-based turbines are being installed at a rapid pace globally.

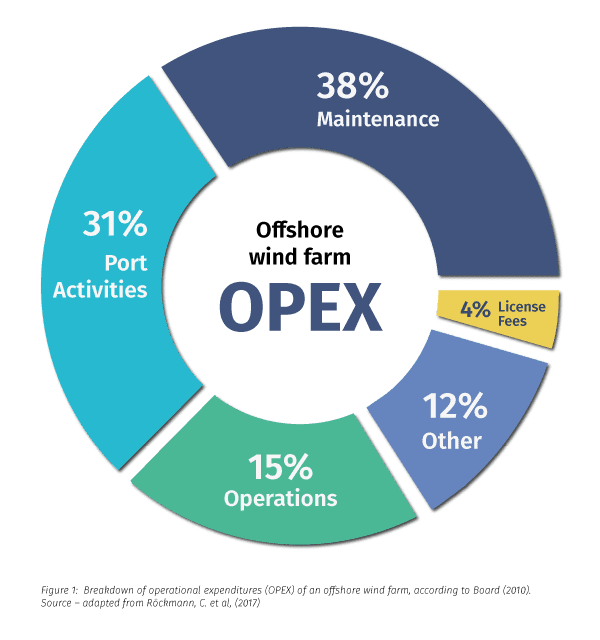

Yet, despite the rapid rise of proven offshore wind renewable technologies, the inflated costs associated with offshore wind farm operation and maintenance are preventing the technology from gaining wider, and more impactful implementation.

Compared to fossil fuel production, the costs associated with offshore wind operation and maintenance are the highest among all energy technologies, representing an average of 25-30% of entire project cost1. Although efforts have been made to reduce this percentage, wind farm maintenance remains comparably high. The advent of intelligent software, however, is clearly a potential game-changer for containing costs. Risk and reliability-based models utilizing optimizing software project up to 23% reduction in annual maintenance cost, while other applied opportunistic maintenance strategies show a potential for a 32% decrease in production loss and transportation cost (Tusar et al. 2021)2.

These findings indicate that digital solutions such as those offered by Shoreline that optimize O&M by driving down costs, improving asset reliability and availability, and ensuring more continuous production, will soon render future projects more financially feasible, and lead to growing support of and investment in wind renewable energy.

An overview of offshore O&M activities and their related challenges

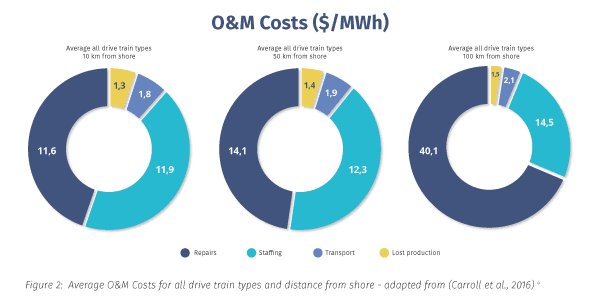

A high percentage of the increased O&M costs outlined above are a direct result of challenges related to access. While most scheduled activities for both onshore and offshore wind farms are similar, the cost of performing these tasks at sea incurs much higher associated costs. Compared to land-based operations, offshore activities often require specialized and additional resources including outfitted vessels, helicopter transports, specially trained personnel, and more intensive procedural operations.

Offshore planners and operators are keenly aware that making O&M activities more efficient by streamlining activities including personnel scheduling and dispatching as well as vessel routing can vastly reduce both OPEX and pressure on personnel, vessels, and resources. Identifying activities where optimization can improve procedures requires a thorough understanding of the specific activities performed and the subsequent cost-and-resource challenges these operations present.

The European Committee for Standardization has categorized maintenance activities performed at wind power systems into three main types: corrective maintenance, preventive maintenance, and condition-based maintenance3.

Challenges specific to offshore wind farm maintenance fall under three broad categories as follows4:

High crew dispatch costs: Given that offshore turbines are often installed in remote locations, assembling and deploying maintenance teams incur considerable costs for transport and logistics, specialized equipment such as dynamic positioning, and personnel.

High production losses: As larger turbines capable of greater output are deployed, power loss during downtime increases, resulting in higher production loss. These cumulative losses result in reduced revenue and negatively impact project profitability.

Limited accessibility: At many times throughout the year, turbine access is restricted for periods ranging from a few hours to several days due to harsh weather and sea conditions.

These challenges worsen the further the wind farm is from shore.

Challenges unique to offshore personnel

Studies clearly indicate that offshore wind personnel often face formidable challenges while performing their assigned duties. A study published in the Journal of Occupational Medicine and Toxicology (Mette et al., 2017)5, examined offshore workers’ conditions and identified many of the difficulties these workers must contend with daily. Their findings can be summarized as follows:

1. Physical strain

Not surprisingly, workers cite the demands of physical work as the most challenging aspect of working at an offshore wind farm. Not only is the work physically taxing, but many tasks also require work to be performed at great heights and inside installations. During the study, many workers reported wearing safety suits and toting heavy equipment while climbing turbines as especially difficult. Workers also report that the time involved with and conditions of transfer and access to and from installations is likewise physically and psychologically stressful.

According to a survey, the leading cause of reported physical strain is ‘climbing’, most often referring to the tasks of climbing and ascending stairs during offshore work. In addition to tasks involving climbing, technicians are also subject to exposure to noise, vibrations, humidity, cold, heat, and chemical substances, and are often required to lift and carry heavy loads, transport bulky equipment, and work in non-ergonomic positions and cramped spaces6. These physical strains often lead to a reduction in workforce performance and cause delays in the execution of activities and work orders.

The ever-present risk of accidents coupled with often unstable weather further compounds workers reported mental stress.

2. Organization of work

Due to the complex nature of work, many offshore technicians and other personnel follow rotational shift schedules7 with 12-hour shift rotations standard practice. These already tediously long shifts are often extended owing to periods of frequent downtime, for example, when personnel are forced to wait for work to begin during corrective maintenance8 or when there is a shortage of specially trained technicians necessary to complete a specific task.

Scheduling conflicts can also arise if the work necessary to address the fault extends beyond the time parameters set in the work order.

In addition to frequent overtime, workers often experience intense pressure to quickly complete activities because every minute of turbine downtime and repair time incurs heavy financial loss. Waiting times owing to inclement weather conditions and subsequent disruptions to the scheduled workflow require costly, and for workers, stressful, schedule modifications. Scheduling difficulties are further compounded by the fact that offshore duties are often highly specialized, and few personnel are adequaltely trained to perform multiple, specialized tasks.

Communication between offshore and onshore personnel is also an ever-present challenge, especially in the event of a medical emergency. Injured offshore workers are especially at risk as available treatment options are limited and emergency routes can be long and difficult even under the best weather conditions.

3. Environmental factors

Weather is a key component in offshore wind farm operations. Inclement weather conditions often cause costly and stressful interruptions and delays in scheduled operation and maintenance. Turbine design presents another formidable challenge as personnel must adroitly navigate confined spaces on platforms and installations while contending with environmental factors such as high decibels, artificial lighting, vibrations, conditioned air and chlorinated water.

4. Lack of specially trained personnel

Offshore wind farms are generally located far from land, and the number of trained personnel available at any given time is limited. Compared to their land-based counterparts, offshore wind farm personnel must complete more intensive training and develop specialized skills such as rescue training and survival at sea. Already dangerous activities like working at height are often made even riskier due to external conditions including waves, wind, and temperature.

To ensure safety and competency, employers invest enormous time and financial resources into training new employees. Training and skill recertification courses often last multiple days, further impacting routine work order implementation. In addition, newly trained personnel are sometimes unable to adjust to the harsh offshore environment, and therefore resign after a short period. Resignations frequently negatively affect the scheduling and management of work orders and personnel rotations.

5. Waiting time

Transportation challenges

Personnel transport poses another potential barrier to completing work orders within the scheduled timeframe. At offshore locations, vessels are usually deployed to access wind turbines for maintenance and repair work. Routine vessel maintenance and personnel training are necessary to prevent costly breakdowns that in turn, further disrupt routine maintenance and operation at wind farm sites. No maintenance or repair can be performed if personnel dispatched for repairs are waiting for a vessel that is delayed or cancelled. In addition, the company must cover rescheduling costs for their crew, secure other methods of transport, and account for the loss of production resulting from asset down time.

Challenging offshore weather

Scheduling offshore operation performance relies heavily on weather conditions. To ensure safe operations, work orders are scheduled when weather forecast parameters fall below defined thresholds for both wind speed and wave height9, with wave height the most critical weather-related limiting factor (in terms of both magnitude and persistence)10. Harsh weather often restricts access to wind turbines, slows down or stops maintenance activities, and limits the amount of power produced. Four main weather-related areas of impact have been identified as:

1. Significant wave height preventing timely technician transfers between transport vessels and wind turbines

2. Significant wave height disrupting jack up vessel operations.

3. Wind speed impacting jack-up lifting operations.

4. Wind speed affecting power production.

Grid failures affecting work order completion

For an offshore wind farm to operate smoothly, its interconnected power grid must be stable at all times. Technical issues can cause grid outages and thus affect the entire wind farm cluster. Oftentimes after a grid restoration, many wind turbines will require troubleshooting maintenance to bring them back online. This troubleshooting process can extend for days, especially during harsh weather conditions, or when skilled resources are limited.

The Shoreline Advantage

As clearly illustrated above, the challenges offshore operators and personnel must contend with are many, and formidable to overcome. Wind farm operators understand the enormous financial stakes involved and the need to reduce costs and prevent downtime however possible. At the same time, operators must ensure the safety of their employees and contractors. Making even minor gains in reducing some of the challenges listed above has been shown to significantly reduce costs and alleviate pressure on already stretched personnel and resources. For example, stakeholders that can render maintenance activities more efficient by streamlining maintenance schedules and vessel routing stand to save tens or even hundreds of thousands of dollars every day in cost and increased production.

In their efforts to discover and implement more cost-and-resource efficient practices, wind farm operators are increasingly relying on intelligent optimization tools specifically engineered for use within the wind industry. For example, work orders are essential documents detailing maintenance activities and give personnel the information they need to organize, assign, prioritize, track, and complete key tasks. Given ever-increasing wind farm size and complexity, work orders are a crucial component in planning and scheduling maintenance activities.

Several studies show that adopting an opportunistic maintenance approach can significantly reduce maintenance costs and save time11. To achieve the maximum benefit, researchers recommend implementing a holistic opportunity-based strategy (HOST). The HOST method adopts a multi-staged structure within a long-term planning stage (work orders are found and prioritized) followed by a short-term operational phase (day-ahead maintenance schedule). The HOST method is manageable, efficient, scalable, and flexible enough to handle large and multiple work orders in a minimum amount of time12.

Shoreline’s work order and integrated resource and planning management solutions enable organizations to implement optimized O&M strategies to achieve HOST and realize immediate cost-saving benefits. Currently, many of the largest wind farm operators rely on Shoreline Wind’s Execution™ SaaS suite of solutions to streamline operations, improve scheduling, reduce manual data handling, and simplify reporting. Overwhelmingly, the evidence shows that organizations implementing reliable digital solutions improve workflows, reduce administration costs and human error, and save thousands of dollars in personnel costs per project. These same organizations also vastly improve their information sharing capabilities and better ensure that project decisions are data-driven and easily auditable.

Shoreline’s groundbreaking Execution™ SaaS is comprised of seven distinct, flexible and customizable solutions engineered to fully integrate within your digital landscape and deliver powerful results.

CMMS — Monitor and execute required maintenance and reporting in one comprehensive data dashboard.

Construction Management — Generate accurate estimates, decrease time-to-production, and optimize resource utilization via streamlined workflow, planning, and reporting process development.

DPR — Ensure transparency and compliancy and reduce downtime with advanced digital reporting.

Enterprise Asset Management — Gain unprecedented and complete overview of your entire field of operations, optimize and monitor asset status with out-of-the box operations management solutions.

Field Service — Give workers the mobile connectivity and processes they need to deliver optimal service across projects and teams.

Marine Coordination — Ensure safe and efficient offshore operations via marine management software engineered by wind industry experts to meet offshore operator and turbine OEM requirements.

Resource Management & Planning — Quickly review resource availability and assign personnel and logistics to projects based on qualifications, certificates and availability.

Shoreline’s Execution™ : Optimize wind farm construction and O&M management

Shoreline solutions are engineered for the wind industry, by some of the world’s leading experts in wind farm construction and O&M technologies and can be used in any location and on any device, including areas of low or no bandwidth. Worldwide, our powerful, adaptable, and flexible plug ‘n play solutions are helping wind farm owners and operators realize millions in OPEX savings every year.

Get in touch with us and learn how your organization stands to benefit with Shoreline.

Authors: Bertrand Barouti, Production Manager – ExecutionTM & Michelle Juel Larsen, Content Developer at Shoreline Wind.

***

Reach out to info@shoreline.no to learn more and discuss how we can add more value to your business.

About Shoreline

Shoreline Wind Inc provides enterprise solutions for the wind industry using intelligent data integration and simulation software to optimize and execute wind farm construction, asset management and business cases, and solutions are deployed globally with the world’s largest energy companies, OEMs, service companies and consultants.

Send media inquiries here.

Article sources: 1 Röckmann, C., Lagerveld, S., Stavenuiter, J. (2017). Operation and Maintenance Costs of Offshore Wind Farms and Potential Multi-use Platforms in the Dutch North Sea. In: Buck, B., Langan, R. (eds) Aquaculture Perspective of Multi-Use Sites in the Open Ocean. Springer, Cham. https://doi.org/10.1007/978-3-319-51159-7_4 / 2 Tusar, Md Imran & Sarker, Bhaba. (2021). Maintenance cost minimization models for offshore wind farms: A systematic and critical review. International Journal of Energy Research. 46. 10.1002/er.7425. / 3C. A. Irawan, D. Ouelhadj, D. Jones, M. Stålhane, and I. B. Sperstad, ‘Optimisation of maintenance routing and scheduling for offshore wind farms’, Eur. J. Oper. Res., vol. 256, no. 1, pp. 76–89, Jan. 2017, doi: 10.1016/j.ejor.2016.05.059. / 4 Carroll, J., McDonald, A., Dinwoodie, I., McMillan, D., Revie, M. and Lazakis, I., 2016. Availability, operation and maintenance costs of offshore wind turbines with different drive train configurations. Wind Energy, 20(2), pp.361-378. / 5 Mette, J., Velasco Garrido, M., Harth, V., Preisser, A. and Mache, S., 2017. “It’s still a great adventure” – exploring offshore employees’ working conditions in a qualitative study. Journal of Occupational Medicine and Toxicology, 12(1). / 6Velasco Garrido M, Mette J, Mache S, et al A cross-sectional survey of physical strains among offshore wind farm workers in the German exclusive economic zone. BMJ Open 2018;8: e020157. doi: 10.1136/bmjopen-2017-020157 / 7 M. Bowles, ‘What is offshore life really like?’, Quanta part of QCS Staffing, Jul. 17, 2018. http://www.quanta-cs.com/blogs/2018-7/what-is-offshore-life-really-like (accessed Jul. 11, 2022). / 8 ‘What Is It Like to Work as a Wind Farm Technician?’, UTM Consultants, Jul. 16, 2022. https://www.utmconsultants.com/news/what-is-it-like-to-work-as-a-wind-farm-technician/41502/ (accessed Jul. 16, 2022). / 9 Yürüşen, N. Y., Rowley, P. N., Watson, S. J., & Melero, J. J. (2020). Automated wind turbine maintenance scheduling. Reliability Engineering and System Safety, 200, [106965]. https://doi.org/10.1016/j.ress.2020.106965 / 10 M. H. Rothkopf, J. K. McCarron and S. Fromovitz, A Weather Model for Simulating Offshore Construction Alternatives, Management Sci. 20 (1974), 1345-1349 / 11 M. Li, X. Jiang, and R. R. Negenborn, ‘Opportunistic maintenance for offshore wind farms with multiple-component age-based preventive dispatch’, Ocean Eng., vol. 231, p. 109062, Jul. 2021, doi: 10.1016/j.oceaneng.2021.109062. / 12 P. Papadopoulos, D. W. Coit, and A. A. Ezzat, ‘Seizing Opportunity: Maintenance Optimization in Offshore Wind Farms Considering Accessibility, Production, and Crew Dispatch’, IEEE Trans. Sustain. Energy, vol. 13, no. 1, pp. 111–121, Jan. 2022, doi: 10.1109/TSTE.2021.3104982.