Offshore wind in the U.S.: Ambition vs. Reality

Goal

To meet this lofty goal, two offshore projects are currently underway, and an astounding 16 offshore projects are currently awaiting permits.

Aside from the expected, and not insignificant planning, regulatory and supply-side hurdles site planners must jump over before wind farm construction can begin, a huge barrier – and one wholly unique to the U.S. offshore market – is already hobbling progress and driving up per diem costs in the $100,000s: the near complete lack of Jones Act compliant wind turbine installation vessels (WTIV) capable of carrying and installing increasingly gargantuan turbine blades and other parts.

As a workaround to these restrictions while compliant WTIV are being built or retrofitted, feeder vessels – generally consisting of Jones Act compliant tugs and barges – are being pressed into service transporting turbine components, equipment, and personnel to and from WTIV jack-up vessels anchored to the seabed at offshore build locations.

As it stands, vessel procurement and retrofitting represent the lion’s share of offshore scale-up spend in the U.S., as evidenced in the case of the much-anticipated, first-ever U.S. built WTIV vessel Charybdis.

With a price tag of over $500 million, the cost to build Charybdis alone outpaces the cumulative amount spent on procuring U.S. wind farm leases to date.

To put these costs into perspective, by many estimates, a staggering 10 years of production with delivery of between 3,500 to 4,000 megawatts of offshore wind capacity is necessary for a single WTIV like Charybdis to achieve positive ROI.

Given the tremendously high financial stakes at hand, coupled with the current energy crises reverberating from the Ukrainian invasion, the need to increase clean, reliable, and renewable energy sources efficiently and quickly in the U.S. is more salient than ever before. With Jones Act restrictions adding a significant layer of complications to an already challenging proposition, U.S. site planners and operators find themselves facing formidable obstacles to overcome.

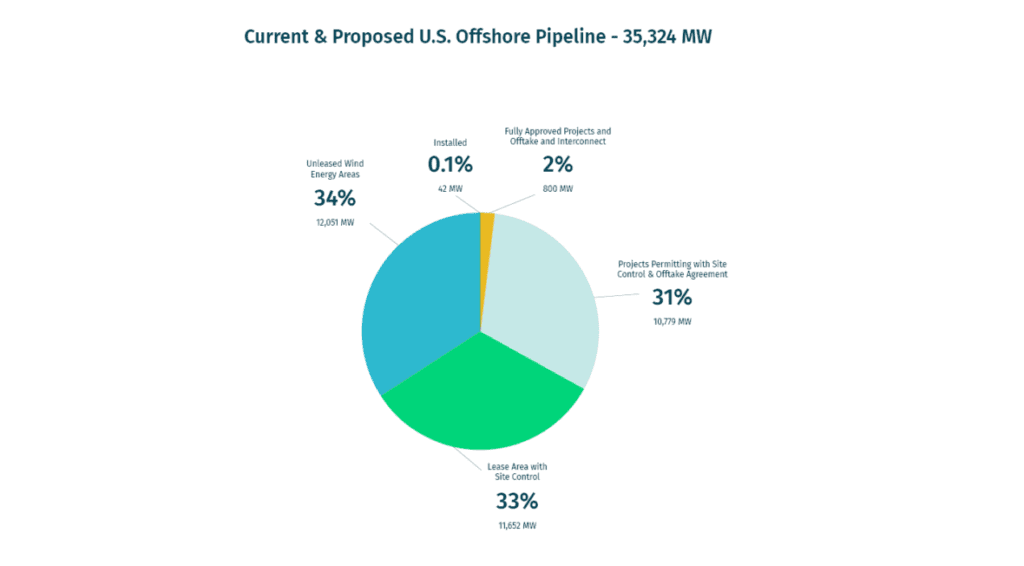

Original illustration 2: Visualization of U.S. offshore wind pipeline classifications by state. Data source: U.S. Department of Energy, Offshore Wind Market Report 2021 Edition.

A complex case: U.S. offshore installation logistics.

Out of sheer necessity, U.S. site planners and installers are utilizing feeder-based installation as a viable, if complicated workaround to restrictions posed by the Jones Act and will continue to do so for the foreseeable future. Yet, while the solution may be workable, is feeder-based installation, with its myriad vessel configurations and supply chain variables compounded by scores of regulations, delivering optimally in terms of operating cost and effectiveness?

Breaking bottlenecks, accurately estimating risk, and improving financial viability from planning to installation requires feeder-based project managers and installers to acquire on-demand, granular, and detailed oversight of every asset along the entire supply chain – no small task given feeder-based supply chain complexity.

A logistical game changer: Advanced simulation of feeder/based offshore wind installation projects.

Across industries, the emergence of advanced simulation technologies is helping to solve even the most intricate logistical and regulatory impacted operations and is saving corporations billions annually by providing actionable optimization insights.

Offshore wind operations are no exception and are already reaping huge cost-and-resource benefits and saving millions annually by implementing intelligent, enterprise software-as-service solutions (SaaS) to virtually plan, model, and simulate offshore wind renewables at every lifecycle stage.

Feeder-based installation, with its even more complex supply chains and logistics than traditional offshore wind projects, requires advanced modeling software to optimize operations and minimize resource spend from planning to installation and beyond by generating actionable data insights in four key areas:

Complex project estimating

Driving costs down requires ongoing installation and operational innovation, and here is the exact point where agent-based modeling excels over conventional mathematical or analytical methods.

Specifically engineered to meet the unique set of challenges inherent in complex supply chains and logistics, agent-based modeling gives project planners and operators the ability to model each system asset independently. This distinction, when applied to offshore installation, offers enormous benefits in terms of data aggregation. For example, a mathematical model is limited to data input, such as monthly turbine installation rates and variable weather stats.

Agent-based modeling, however, captures minute details across all operations, from pre-assembly, loadout and transport, and installation and commissioning, to deliver real-life, simulation scenario data needed to generate installation campaign estimates with accuracy and precision.

Asset configuration and variable modeling

Agent-based solutions offer another clear advantage over traditional modeling methods by making it possible to consolidate project output estimates, such as weather downtime, monthly workability, asset availability and downtime, project and personnel management and scheduling, and more into one simulation model.

This cohesive, virtual overview gives planners and operators the ability to identify interdependencies between various assets and address and resolve risks, weaknesses, and potential knock-on effects before construction begins.

Likewise, agent-based modeling delivers realistic, and acutely accurate and granular predictions of, for example, fuel consumption, air hours, turbine offline hours, transfer, and vessel downtime resulting from weather and other events.

Full lifecycle scenario modeling

Given the increasingly complex scenarios associated with feeder-based installation, spreadsheet data entry quickly becomes an outdated mode of capturing asset and resource variables, and next to impossible to glean usable insights from.

Agent-based modeling eliminates tedious manual input and knocks down information silos by consolidating data from fabrication, component transport, pre-assembly, loadout, installation, commissioning, and testing. Once the asset detail and variable picture is complete, precise project simulations and performance estimates can be generated within minutes.

Process and resource optimization

Given the exponential scale-up and complexity of the U.S. offshore wind market, the ability to analyze installation operations quickly and accurately is urgently needed. Only today’s smart, agent-based models are capable of meeting that challenge and delivering accurate, full life cycle project analyses based on variable data to key decision makers.

Agent-based modeling also makes static reporting a relic of the past. Enable cost-saving, real-time decision making with flexible, on-the-fly customizable scenario presentations, including edge cases, and real-time variable adjustments generated within minutes.

Shoreline’s Design™ the global industry standard in wind simulation and optimization

Since its debut in 2014, Design™, Shoreline’s intelligent, patented algorithm-driven simulation SaaS has emerged as the industry’s only comprehensive agent-based modeling solution proven to significantly reduce installation and operating costs while increasing time-to-production by delivering on-demand, full lifecycle modeling across the entire field of operations.

Design™ continuously evolves its modeling capabilities to meet emerging and expanding wind technologies, development requirements and standards, at all levels of complexity, making it the ideal simulation solution for feeder-based installation project optimization.

Shoreline’s Design™ allows us to compare different logistical solutions for all construction phases of an offshore wind farm either at a high or detailed level depending on client’s needs.

We use the high-quality output to assess different logistical options and optimize the construction strategy with regards to risk and cost. The visualization of the installation processes and the comprehensive output section is key in our client centric results delivery.

— Raya Peterson, Team Lead Strategy and Risk at Rambøll

***

Summary

Optimizing the unprecedented, rapid buildup of feeder-based offshore wind installations in the U.S., requires fast and accurate simulation software that can model increasingly complex scenarios. Agent-based modeling is a proven method to quickly deliver accurate, actionable data.

Design™, the industry-standard in agent-based modeling simulation provides the granular insight and flexibility feeder-based installation project managers and operators need to reduce resource spend, increase time-to-production and ultimately, maximize ROI.

Author: Michelle Juel Larsen, Content Developer at Shoreline Wind.

***

Reach out to info@shoreline.no to learn more and discuss how we can add more value to your business.

About Shoreline Wind Inc.

Shoreline Wind Inc provides enterprise solutions for the wind industry using intelligent data integration and simulation software to optimize and execute wind farm construction, asset management and business cases, and solutions are deployed globally with the world’s largest energy companies, OEMs, service companies and consultants.

Send media inquiries here.